ZCORE: Seaweed Residues for Superior Bio-Coatings

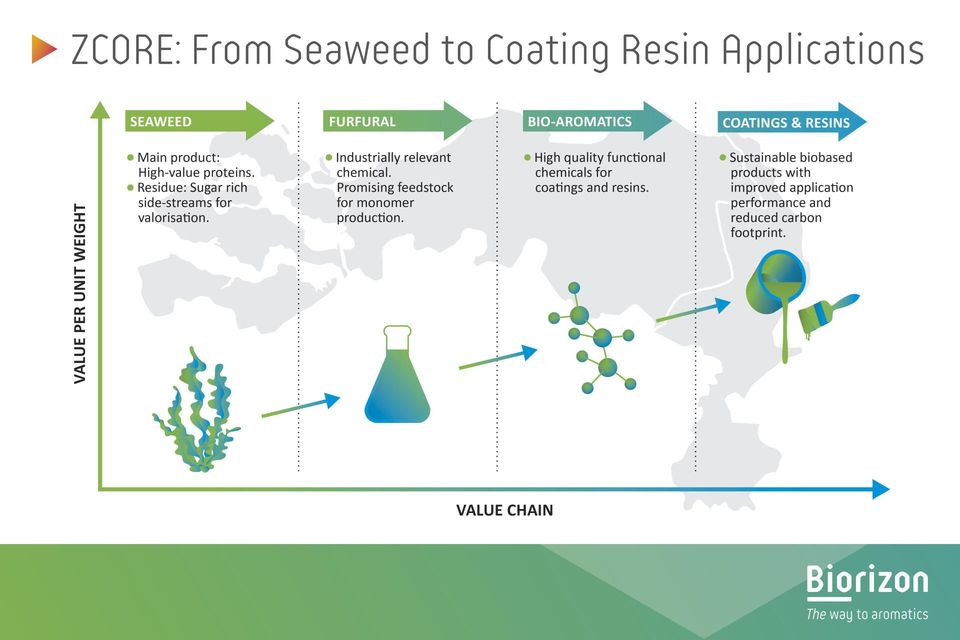

In the ZCORE project, 6 partners (among which Relement) have joined forces to demonstrate that seaweed residues can be utilized for the production of biobased coatings (paints) with superior application properties.

Climate agreement: fast-growing seaweed ideally suited to reduce CO₂

With the Climate Agreement, the Netherlands is committed to a greenhouse gas reduction of 49% in 2030 compared to 1990. For the chemical industry, this means, among other things, that by 2030 the share of biobased raw materials will have to quadruple compared to 2016 (from 4% to 15%). Seaweed is ideally suited for this: with an increase of 30% per day, it is one of the fastest growing plants. Furthermore, because of its cultivation at sea, it does not compete with land-growing biomass. To conclude, seaweed contains, in addition to proteins for food applications, residual sugars and these non-edible sugars can be a valuable raw material for the chemical industry.

40% of all chemicals are aromatic; the greening potential is enormous

The sugars from seaweed residual flows can be converted into bio-aromatics. Of all chemicals produced by the chemical industry, 40% are aromatic in nature. It represents a global annual volume of 122 million tons, worth more than 115 billion euros and has an annual growth of 4-5%. Aromatics are used in plastics, paints, additives such as UV stabilizers and pigments, fibers, cosmetics, pharmaceuticals and food ingredients such as vitamins, colorants and flavouring additives. So far, aromatics are extracted from petroleum and this has a negative impact on the climate. That is why finding renewable feedstock is urgent.

Shared Research Center Biorizon: The Way to Aromatics

Biorizon is the most advanced and valued research program in bio-aromatics worldwide. Shared Research Center Biorizon, an initiative of TNO and VITO, has been co-creating technologies for the commercial production of bio-aromatics since 2013 at the Green Chemistry Campus in Bergen op Zoom. Together with industrial partners, Biorizon develops innovative technologies to use residual biomass and recycle streams for the production of bulk and specialty aromatics. The ZCORE project is a good example of this.

More durable and cost-effective coatings with superior properties

In the ZCORE project (from Seaweed to COating REsin applications), seaweed residues are converted into bio-aromatics and these will be tested in coatings, among other things. The coating industry is keen to develop a fully biobased coating in order to respond to the climate objectives as well as market demand. The ZCORE project is specifically working on 100% biobased alkyd resins (paint). So far, a content of 50-60% biobased has been achieved because no bio-aromatics were available on a sufficiently large scale. ZCORE changes this. In addition to doubling the sustainability, ZCORE also brings potential cost reductions because Biorizon has developed a unique shortened route for the production of functionalized bio-aromatics compared to the fossil production route. Finally, the bio-aromatics also bring improved properties including superior wear resistance, gloss and UV resistance.

These three advantages allow this bio-coating to be competitive with fossil-based coatings. With a global coating market of 4 Mton on an annual basis, this means a huge breakthrough in the field of 100% biobased coatings and this will accelerate the realization of a biobased economy.

ZCORE project partners represent entire value chain

The ZCORE project brings together the entire value chain for the valorization of seaweed in bio-aromatics and its application in coatings.

The SME partners Relement and Engineering Chemicals, together with 5 leading coating producers, form an important link to practice with their knowledge of seaweed production and applications of bio-aromatics in industrially relevant applications (such as coatings). The knowledge institutes TNO, Avans and Maastricht University have leading knowledge and technology in the field of biorefining, bio-aromatics production, coating resins and sustainability analyses. In addition to its function as headquarters, the Green Chemistry Campus is also involved in dissemination activities and interaction with SMEs.

Strengthening the biobased economy in the South of the Netherlands

The South Netherlands region has a unique potential for growing seaweed, unlocking the biomass and making it suitable as raw material for the chemical industry via (bio) chemical conversion technology. The region houses a large number of agro and chemical companies and there are strong partnerships between knowledge institutes and industry. The biobased economy is a spearhead in the Regional Innovation Smart Specialization Strategy (RIS3) of the Southern Netherlands, with a focus on green raw materials and green building blocks. The link between the knowledge platforms in the fields of seaweed production and refining (Zeeland), bio-aromatics production (Brabant) and in the fields of coating resins and sustainability (Limburg) within ZCORE results in a broadening and strengthening of the open innovation system.

OPZuid

The ZCORE project is made possible by the European Regional Development Fund and the provinces of Noord-Brabant, Zeeland and Limburg in the context of OPZuid.